Timagwiritsa ntchito fomula ya no-dysprosium pazinthu zozungulira zotsika kuti makasitomala achepetse ndalama.Tili ndi chilinganizo chokhazikika chomwe chitha kupangidwa kukhala zinthu zotsika kwambiri za kutentha.Amachepetsa ndalama ndi kumawonjezera dzuwa kwambiri kwa makasitomala ndi mosamalitsa kulamulira kulolerana pokonza ndi ❖ kuyanika malingana ndi zofunika zosiyanasiyana makasitomala kuonetsetsa bata la plating chitetezo pa nthawi yomweyo, kuphatikizapo kutsitsi mchere, ❖ kuyanika mphamvu yomanga, colloid kuyanjana ndi zina zotero. .

Zozungulira zozungulira zimakhala zosavuta kusowa ngodya pakupanga.Chifukwa chake tili ndi zida zowunikira zodziwikiratu zololera mawonekedwe, zomwe zitha kuwonetsetsa kuti zinthu zili ndi zolakwika mkati mwazowongolera komanso kupewa zinthu zolakwika pogwiritsa ntchito njira.

Pankhani ya kusasinthika kwa flux, timaonetsetsa kuti ng'anjo yokhazikika yokhazikika kuti igwirizane ndi kayendetsedwe ka maginito, ndi zida zowunikira maginito kuti tipewe zinthu zofooka za maginito kuti zisamayendere makasitomala.Pankhani ya ma magnetization ma CD, kampani yathu imatsata zida za magnetization zodziwikiratu kuti anthu asagwiritse ntchito molakwika maginito.

Pankhani ya ulamuliro yobereka, chiwerengero chachikulu cha Mipikisano mizere kudula makina, slicing mayunitsi, okhwima luso processing ogwira ntchito, wangwiro mankhwala ndondomeko polojekiti, sitepe iliyonse ya mankhwala processing ndi kupanga akhoza kupeza patsogolo ndemanga pa nthawi iliyonse, okhwima cylindrical kupanga mankhwala mzere, kuwonetsetsa kuwongolera kwamakasitomala pakubweretsa zinthu, komanso kupita patsogolo kosinthika.

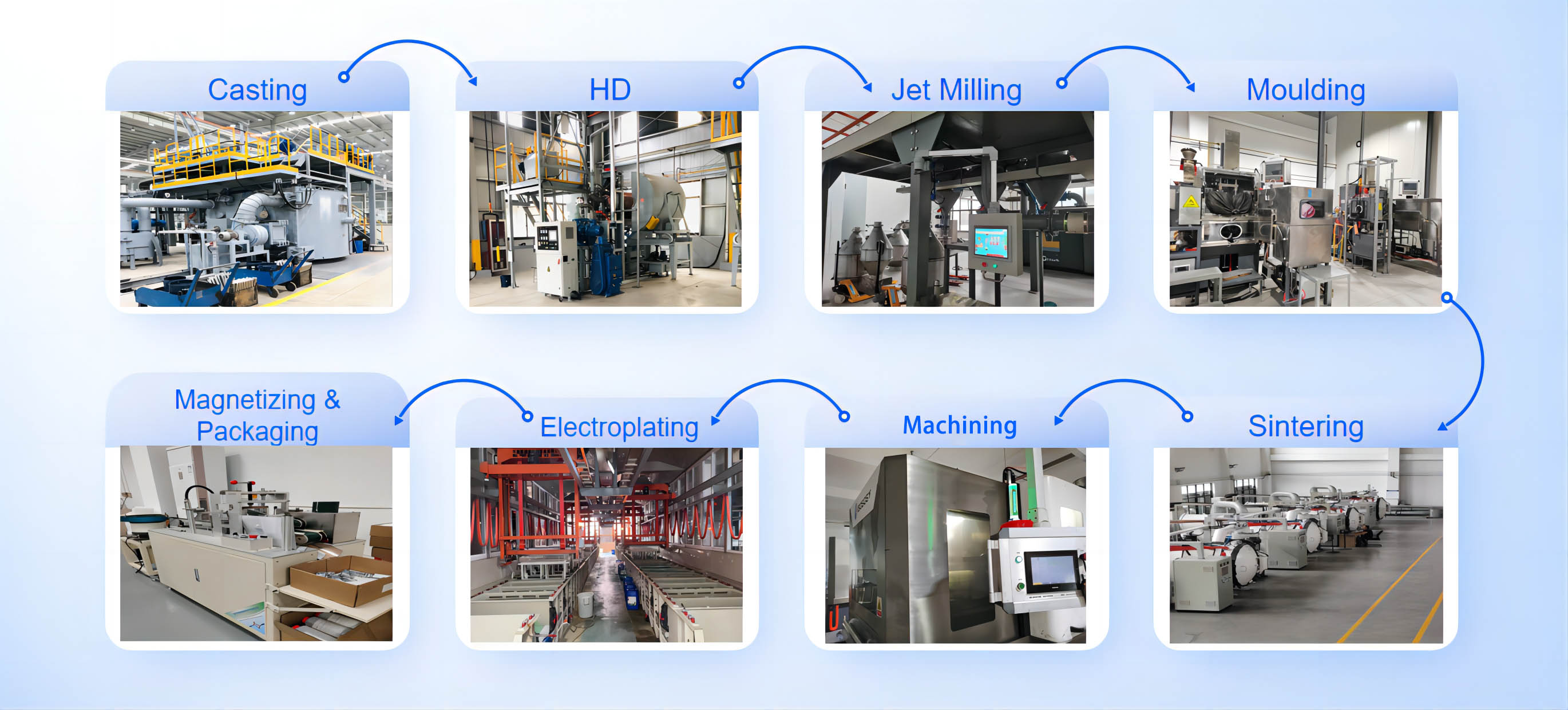

NdFeB Production Process

Coating Introduction

| Pamwamba | Kupaka | Makulidwe μm | Mtundu | Maola a SST | Maola a PCT | |

| Nickel | Ni | 10 - 20 | Siliva Wowala | > 24 ~ 72 | > 24 ~ 72 | |

| Ni+Cu+Ni | ||||||

| Black Nickel | Ni+Cu+Ni | 10 - 20 | Bright Black | > 48-96 | > 48 | |

| Cr3 + Zinc | Zn C-Zn | 5; 8 | Brighe Blue Mtundu Wowala | > 16-48 > 36-72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10-25 | Siliva | > 36-72 | > 48 | |

| Au | Ni+Cu+Ni+Au | 10-15 | Golide | > 12 | > 48 | |

| Ag | Ni+Cu+Ni+Ag | 10; 15 | Siliva | > 12 | > 48 | |

| Epoxy | Epoxy | 10 - 20 | Black/Grey | > 48 | --- | |

| Ndi+Cu+Epoxy | 15-30 | > 72-108 | --- | |||

| Zn+Epoxy | 15-25 | > 72-108 | --- | |||

| Passivation | --- | 1; 3 | Imvi Yakuda | Chitetezo Chakanthawi | --- | |

| Phosphate | --- | 1; 3 | Imvi Yakuda | Chitetezo Chakanthawi) | --- | |

Makhalidwe Athupi

| Kanthu | Parameters | Mtengo Wothandizira | Chigawo |

| Magnetic Wothandizira Katundu | Reversible Temperature Coefficient of Br | -0.08--0.12 | %/℃ |

| Kusintha kwa Kutentha Kokwanira Kwa Hcj | -0.42 ~ 0.70 | %/℃ | |

| Kutentha Kwapadera | 0.502 | KJ ·(Kg ·℃)-1 | |

| Curie Kutentha | 310-380 | ℃ | |

| Mechanical Physical Katundu | Kuchulukana | 7.5-7.80 | g/cm3 |

| Vickers Kuuma | 650 | Hv | |

| Kukaniza Magetsi | 1.4x10-6 | μq m | |

| Compressive Mphamvu | 1050 | MPa | |

| Kulimba kwamakokedwe | 80 | Mpa | |

| Kupindika Mphamvu | 290 | Mpa | |

| Thermal Conductivity | 6 mpaka 8.95 | W/m · K | |

| Young's Modulus | 160 | GPA | |

| Kukula kwa Thermal(C⊥) | -1.5 | 10-6/℃-1 | |

| Kukula kwa Thermal (CII) | 6.5 | 10-6/℃-1 |

Chiwonetsero chazithunzi